Our Palletizer is designed to palletize the stacks of plates coming out of the Plate Stacker in order to reduce manpower and automate the manufacturing plant.

Designed to reduce lead in the air and automatically clean lead dust from the inside of the oven. The unique technology is the only production equipment in the market that will maximize production efficiencies and minimize energy consumption.

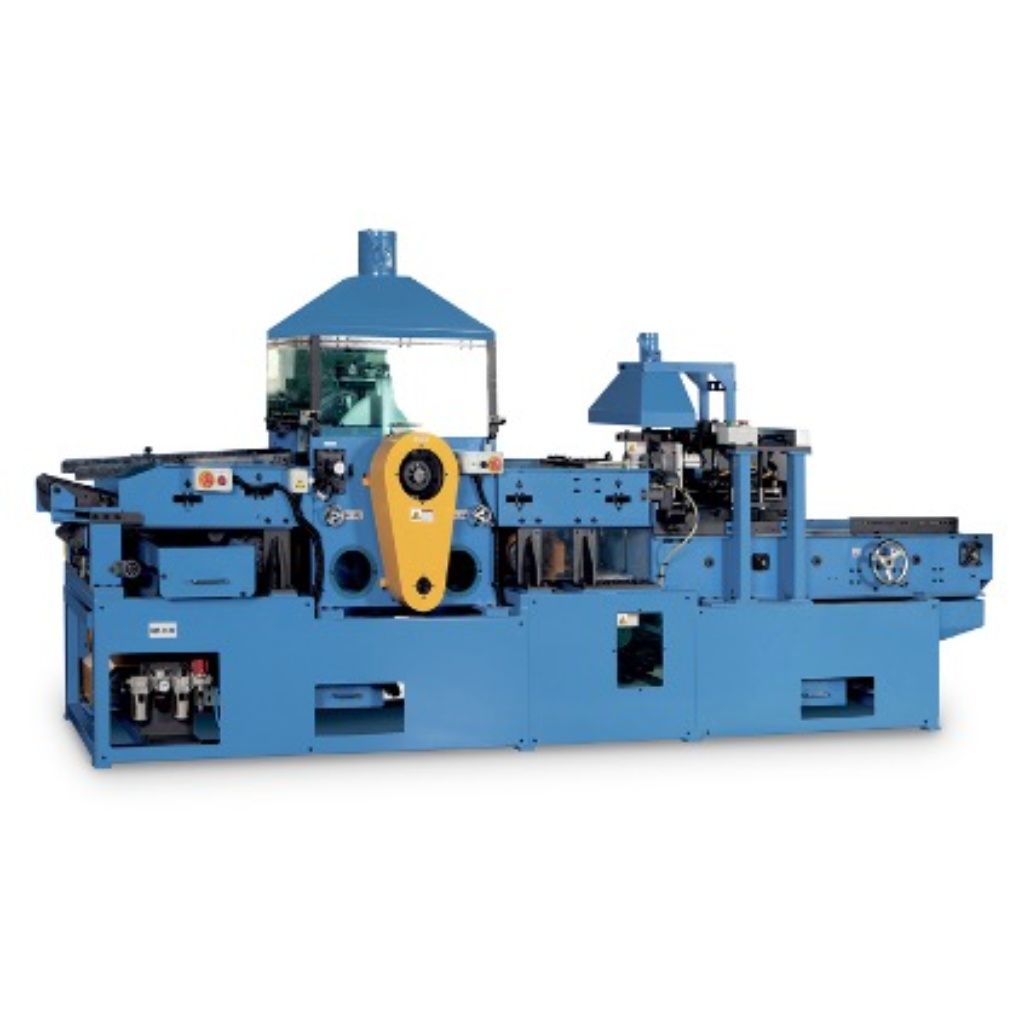

Improved technology with increased pasting & plate quality.

Clean lugs.

Symmetrical Over-pasting 50/50 on bottom and top.

No Belts Required.

Adjust paste thickness while running

Easy to operate.

Minimum Waste.

Fast Paper Shift.

Paper breakage control.

Minimum maintenance.

Our Divider & Diverging Conveyors enable you to choose the one that fits best your applications. In all Dividers stand out the accurate cutting tolerances and the easy maintenance.

One of many challenges to operating an efficient battery production line is utilizing the proper design and sizing of the curing chamber. We offer various solutions specifically designed to meet these challenges.

Continuous production applicable to all kinds of Grids such as Expanded and Punched type.

Precise, fast, reliable process,

quick changeover and operator friendly.

Battery performance is dependent upon the quality of lead oxide used. This

is why our Ball Mill systems have been designed to produce high quality

battery oxide for a wide range of battery types.

Lead acid battery performance is dependent upon the quality of lead oxide used. This is why our Barton oxide systems

have been designed to produce a wide range of high quality oxides for a wide range of battery types.

Need to reduce your battery oxide to a mean particle size =/< 3 micron? Our Hammer

mill is your solution!

Each Hammer Mill is made from heavy walled steel construction with cast iron hammers, regulators, and fan hubs.

The RLF is designed to produce a wide range of Red Lead, using leady oxide feed material, for use in batteries, leaded, glass, ceramics, and specialty chemicals.

We and selected third parties use cookies or similar technologies for technical purposes and, with your consent, for other purposes as set out in the Cookie Policy.

You are free to give, refuse or withdraw your consent at any time by accessing the preferences panel. If you refuse to give consent, certain features may become unavailable.

Use the "Accept All" button to give your consent. Use the "Reject All" button to continue without accepting.