Categories

Main Menu

Produkter

For further information or enquiries, please contact us.

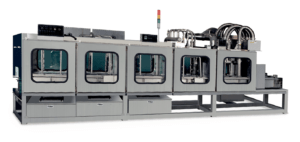

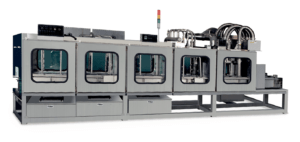

Washing & drying machine

5 stations: 1-3 washing, 4 air blowing and 5 heat blowing. Cycle time approx 8 batteries/min. (based on L3 Battery). Container size L185-410 x W125-180 ...

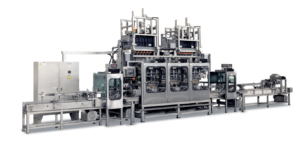

Vacuum ACID filling machine for VRLA

Cycle time approx 4 batteries/min. of L3 Battery. Container size L185-410 x W125-180 x H170-250 mm

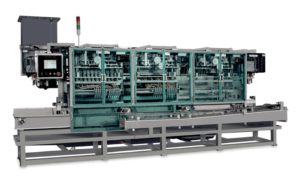

OCV testing & high rate discharging machine

1st step is IR testing (optional), 2nd step is OCV & HRD testing Approx 8 batteries/min. (based on L3 Battery). Changeover time approx. 10 min

Air leak testing machine

Acid proof high strength material and very stable structure for main frame. Cycle time approx 8 batteries/min. of L3 battery. Container size L185-410, W125-180, H170-250 ...

ACID filling machine

Acid proof, high strength material and stable structure frame. Cycle time approx 8 batteries/min. of L3 battery. Applicable battery size L185-410, W125-180, H170-250 mm

ACID dumping machine

Our Acid dumping machine is composed of very strong acid resistant material. Rotation type dumping machine uses revolving drum which has 4 sections.

S2000 Enveloper

S2000 capacity 130 Env./min. Plate types: Cast grids, Expanded metal, Concast or Punched. Plate width 100-150 mm Plate height 100-150 mm Plate thickness 1-2 mm ...

S85 & M85 Enveloper

S85 & M85 capacity 80-90 Env./min. Plate types: Cast grids, Expanded metal, Concast or Punched. Plate width 102-152mm Plate height 102mm-152mm Sealing margin 7mm (.28”) ...

HV350 Enveloper

Enveloper HV350 for SLI batteries. Capacity 150 Env./min. Plate types: Cast grids, Expanded metal, Concast or Punched. Plate width: 106-142 mm. Plate height 90-150 mm. ...

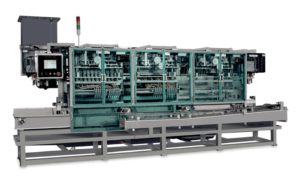

COS II-b (For PE, EFB & AGM)

Cycle Time approx. 4.5 batteries/min for PE battery. AGM Battery applicable 3 batteries/min. Full automatic operation in each station. Battery type Changeover approx. 20 min ...

COS III (For Truck)

Cycle Time : approx. 2-2.5 batteries/min. 3x2 battery type (1x6 applicable). Full automatic operation Group supplying, loading, lug preparation, alignment, cast-on-strap and unloading. Battery type ...

COS II (For PE & EFB)

Cycle Time approx. 4.5 batteries/min. of L3 battery Automatic operation in each station. Battery type Changeover approx. 20 minutes Dust and fume extraction system for ...

COS I

Cycle Time approx. 3 Batteries/min. based on L2 battery. Semi Automatic Operation Manual Loading/Unloading Station Auto: Aligning, Lug brushing, Fluxing & Drying and Mould Station. ...

Post burning machine

Cycle Time approx. 4.7 Batteries/Min. of L3 Battery Using touch panel for easy operation Precise control of welding depth in terminal and movement of head ...

Partition hole punching machine

Cycle Time approx. 4.7 Batteries/min. of L3 Battery Easy and quick changeover in the touch panel. Linear movement for hole punching, automatic collecting of punched ...

LID sealing machine

Cycle Time approx. 4.7 Batteries/min. of L3 Battery Better sealing quality of plastic material by speed control of melting and sealing. Easy and quick changeover ...

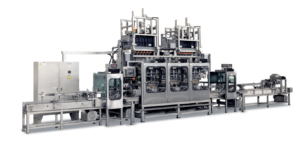

Combi machine

Cycle Time approx. 4.7 Batteries/min. of L3 battery. Reject station included after short circuit tester and Quick changeover by push button on touch screen.

Air leak testing

Cycle Time approx. 4.7 Batteries/min. of L3 Battery AGM Battery applicable (Option). Leak tester (2 heads) Using Fukuda testing unit (Accuracy: 0.00015kg cm2). MFG. code ...

Uncoiler

Continuous production applicable to all kinds of Grids such as Expanded and Punched type. Can be used with wooden pallet or with plastic pallet.

Paste mixing system

Complete batching and dispensing of the raw materials into the mixing process. Oxide, water, acid, fiber, expander, and other ingredients. The Oxide, water and acid ...

Palletizer

Our Palletizer is designed to palletize the stacks of plates coming out of the Plate Stacker in order to reduce manpower and automate the manufacturing ...

Flash drying oven

Designed to reduce lead in the air and automatically clean lead dust from the inside of the oven. The unique technology is the only production ...

Drum paster

Improved technology with increased pasting & plate quality. Clean lugs. Symmetrical Over-pasting 50/50 on bottom and top. No Belts Required. Adjust paste thickness while running ...

Divider & Diverging Conveyor

Our Divider & Diverging Conveyors enable you to choose the one that fits best your applications. In all Dividers stand out the accurate cutting tolerances ...

Curing chamber

One of many challenges to operating an efficient battery production line is utilizing the proper design and sizing of the curing chamber. We offer various ...

Auto plate stacker

Continuous production applicable to all kinds of Grids such as Expanded and Punched type. Precise, fast, reliable process, quick changeover and operator friendly.

Red lead

The RLF is designed to produce a wide range of Red Lead, using leady oxide feed material, for use in batteries, leaded, glass, ceramics, and ...

Hammer mills

Need to reduce your battery oxide to a mean particle size =/< 3 micron? Our Hammer mill is your solution! Each Hammer Mill is made ...

Barton Reactor

Lead acid battery performance is dependent upon the quality of lead oxide used. This is why our Barton oxide systems have been designed to produce ...

Ball mill

Battery performance is dependent upon the quality of lead oxide used. This is why our Ball Mill systems have been designed to produce high quality ...

Washing & drying machine

5 stations: 1-3 washing, 4 air blowing and 5 heat blowing. Cycle time approx 8 batteries/min. (based on L3 Battery). Container size L185-410 x W125-180 ...

Vacuum ACID filling machine for VRLA

Cycle time approx 4 batteries/min. of L3 Battery. Container size L185-410 x W125-180 x H170-250 mm

OCV testing & high rate discharging machine

1st step is IR testing (optional), 2nd step is OCV & HRD testing Approx 8 batteries/min. (based on L3 Battery). Changeover time approx. 10 min

Air leak testing machine

Acid proof high strength material and very stable structure for main frame. Cycle time approx 8 batteries/min. of L3 battery. Container size L185-410, W125-180, H170-250 ...

ACID filling machine

Acid proof, high strength material and stable structure frame. Cycle time approx 8 batteries/min. of L3 battery. Applicable battery size L185-410, W125-180, H170-250 mm

ACID dumping machine

Our Acid dumping machine is composed of very strong acid resistant material. Rotation type dumping machine uses revolving drum which has 4 sections.

S2000 Enveloper

S2000 capacity 130 Env./min. Plate types: Cast grids, Expanded metal, Concast or Punched. Plate width 100-150 mm Plate height 100-150 mm Plate thickness 1-2 mm ...

S85 & M85 Enveloper

S85 & M85 capacity 80-90 Env./min. Plate types: Cast grids, Expanded metal, Concast or Punched. Plate width 102-152mm Plate height 102mm-152mm Sealing margin 7mm (.28”) ...

HV350 Enveloper

Enveloper HV350 for SLI batteries. Capacity 150 Env./min. Plate types: Cast grids, Expanded metal, Concast or Punched. Plate width: 106-142 mm. Plate height 90-150 mm. ...

COS II-b (For PE, EFB & AGM)

Cycle Time approx. 4.5 batteries/min for PE battery. AGM Battery applicable 3 batteries/min. Full automatic operation in each station. Battery type Changeover approx. 20 min ...

COS III (For Truck)

Cycle Time : approx. 2-2.5 batteries/min. 3x2 battery type (1x6 applicable). Full automatic operation Group supplying, loading, lug preparation, alignment, cast-on-strap and unloading. Battery type ...

COS II (For PE & EFB)

Cycle Time approx. 4.5 batteries/min. of L3 battery Automatic operation in each station. Battery type Changeover approx. 20 minutes Dust and fume extraction system for ...

COS I

Cycle Time approx. 3 Batteries/min. based on L2 battery. Semi Automatic Operation Manual Loading/Unloading Station Auto: Aligning, Lug brushing, Fluxing & Drying and Mould Station. ...

Post burning machine

Cycle Time approx. 4.7 Batteries/Min. of L3 Battery Using touch panel for easy operation Precise control of welding depth in terminal and movement of head ...

Partition hole punching machine

Cycle Time approx. 4.7 Batteries/min. of L3 Battery Easy and quick changeover in the touch panel. Linear movement for hole punching, automatic collecting of punched ...

LID sealing machine

Cycle Time approx. 4.7 Batteries/min. of L3 Battery Better sealing quality of plastic material by speed control of melting and sealing. Easy and quick changeover ...

Combi machine

Cycle Time approx. 4.7 Batteries/min. of L3 battery. Reject station included after short circuit tester and Quick changeover by push button on touch screen.

Air leak testing

Cycle Time approx. 4.7 Batteries/min. of L3 Battery AGM Battery applicable (Option). Leak tester (2 heads) Using Fukuda testing unit (Accuracy: 0.00015kg cm2). MFG. code ...

Uncoiler

Continuous production applicable to all kinds of Grids such as Expanded and Punched type. Can be used with wooden pallet or with plastic pallet.

Paste mixing system

Complete batching and dispensing of the raw materials into the mixing process. Oxide, water, acid, fiber, expander, and other ingredients. The Oxide, water and acid ...

Palletizer

Our Palletizer is designed to palletize the stacks of plates coming out of the Plate Stacker in order to reduce manpower and automate the manufacturing ...

Flash drying oven

Designed to reduce lead in the air and automatically clean lead dust from the inside of the oven. The unique technology is the only production ...

Drum paster

Improved technology with increased pasting & plate quality. Clean lugs. Symmetrical Over-pasting 50/50 on bottom and top. No Belts Required. Adjust paste thickness while running ...

Divider & Diverging Conveyor

Our Divider & Diverging Conveyors enable you to choose the one that fits best your applications. In all Dividers stand out the accurate cutting tolerances ...

Curing chamber

One of many challenges to operating an efficient battery production line is utilizing the proper design and sizing of the curing chamber. We offer various ...

Auto plate stacker

Continuous production applicable to all kinds of Grids such as Expanded and Punched type. Precise, fast, reliable process, quick changeover and operator friendly.

Red lead

The RLF is designed to produce a wide range of Red Lead, using leady oxide feed material, for use in batteries, leaded, glass, ceramics, and ...

Hammer mills

Need to reduce your battery oxide to a mean particle size =/< 3 micron? Our Hammer mill is your solution! Each Hammer Mill is made ...

Barton Reactor

Lead acid battery performance is dependent upon the quality of lead oxide used. This is why our Barton oxide systems have been designed to produce ...

Ball mill

Battery performance is dependent upon the quality of lead oxide used. This is why our Ball Mill systems have been designed to produce high quality ...